Auto Upholstery Fabric

Auto Upholstery FabricAuto Upholstery Fabric

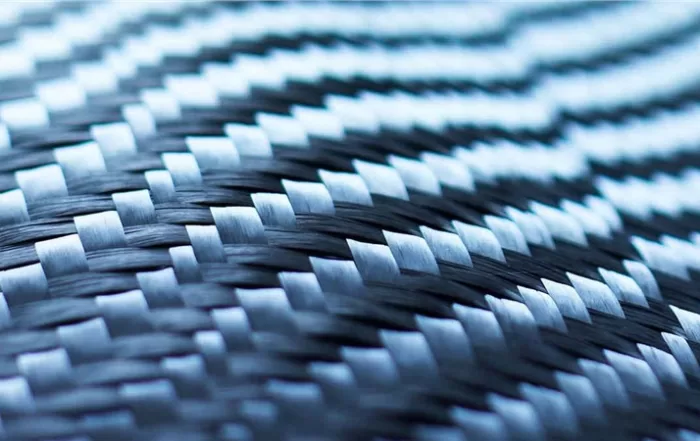

Fabric weaving is the process of creating a fabric by interlacing two sets of threads

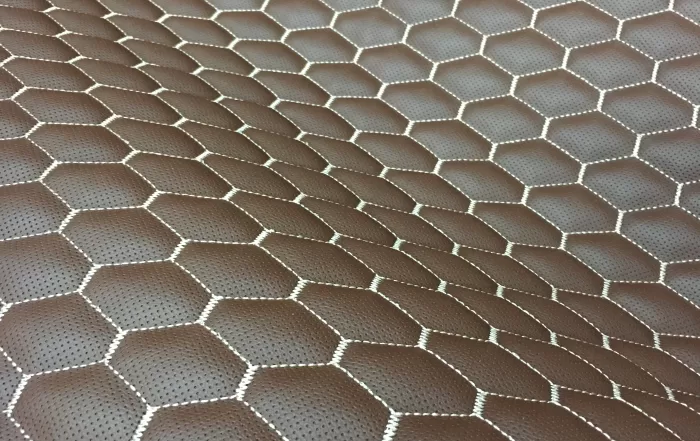

Auto Upholstery Vinyl

Auto Upholstery VinylAuto Upholstery Vinyl

Artificial leather, also known as faux leather or synthetic leather,

Car Seats Covers

Car Seats CoversCar Seats Covers

Car seat covers are protective coverings designed to be placed over the seats of a vehicle to protect them from wear and tear,

Knitted Fabrics

Knitted FabricsKnitted Fabrics

Knitted Fabric

Why PVC Synthetic Leather is Popular in Automotive Seat Covers

Key Performance Criteria for Automotive PVC Leather

When choosing PVC synthetic leather for automotive interiors, the visual appearance is only one part of the story. Behind every successful seat cover or door panel there is a material that meets strict technical requirements for durability, comfort and safety. In this article, we look at the key performance criteria for automotive PVC leather, and explain how Delta Artificial Leather supports OEM and aftermarket customers with reliable solutions.

Abrasion resistance & Martindale values

One of the most important performance indicators for automotive PVC leather is abrasion resistance. Car seats and interior trims are exposed to constant friction from passengers, clothing, seat belts and other objects. If the surface is not resistant enough, it will show premature wear, glossing or even cracking.

In the textile and upholstery industry, abrasion resistance is typically measured with the Martindale test. During this test, the material is rubbed in a controlled way against a standard fabric under a specific load. The result is expressed as the number of cycles the material can withstand before visible damage occurs.

For automotive PVC leather, typical expectations are:

-

High Martindale cycles to ensure long-term performance in daily use

-

Stable surface grain that does not become glossy too quickly

-

No colour transfer or significant change in appearance after the test

When comparing different PVC leathers, buyers should ask for:

-

The Martindale test method used

-

The minimum required value (e.g. for seat applications vs. door trims)

-

Any additional tests for scratch and scuff resistance

At Delta Artificial Leather, we design our PVC leather to achieve the abrasion resistance required for automotive seating and interior trim, helping our customers reduce complaints and warranty issues.

UV and colour fastness in car interiors

Another crucial performance criterion is resistance to light and heat. Car interiors are exposed to sunlight for long periods, especially in hot climates. Poor-quality synthetic leather can fade, discolour or harden over time.

For this reason, UV and colour fastness tests are essential:

-

Colour fastness to light: measures how well the colour resists fading under artificial light that simulates sunlight.

-

Colour fastness to heat and ageing: evaluates changes in colour, gloss and physical properties after exposure to elevated temperature and humidity.

In automotive interiors, colour stability is not just a visual concern. When different materials are combined (fabric, PVC, plastic parts), all components need to keep a harmonised colour over the lifetime of the vehicle. A seat that fades faster than the surrounding trims looks cheap and unprofessional.

Quality automotive PVC leather should offer:

-

Good colour fastness to light, adapted to the target market’s climate

-

Stable gloss level under sunlight and temperature changes

-

Minimal yellowing or discolouration during accelerated ageing tests

Delta Artificial Leather works closely with customers to define target colour fastness levels and runs internal tests to ensure that our PVC leather maintains its original appearance in real driving conditions.

Flame-retardant options and safety standards

Safety is a non-negotiable requirement in the automotive industry. Interior materials must meet specific flammability standards to reduce the risk of fire and limit flame spread in the cabin.

Automotive PVC synthetic leather can be formulated in flame-retardant (FR) versions to help manufacturers comply with these standards. Key points for buyers:

-

Check which fire standards apply in your market (for example, different regions may require different test methods).

-

Confirm that the PVC leather is available in an FR grade suitable for seat upholstery, door panels or headliners.

-

Ask for test reports that show pass/fail results and test conditions.

It is important to balance flame performance with comfort and processability. A well-designed FR PVC leather should still provide a soft touch, good flexibility and reliable processing in cutting, sewing and lamination.

Delta Artificial Leather offers flame-retardant PVC synthetic leather options for various automotive interior applications. We support customers by providing the necessary documentation and by adapting formulations to their specific regulatory requirements.

Backing Fabrics, Thickness and Grain Selection

Behind every good PVC leather, there is a carefully chosen backing fabric. The backing plays a key role in:

-

Overall strength and tear resistance

-

Dimensional stability during cutting and sewing

-

Behaviour in lamination with foam or other substrates

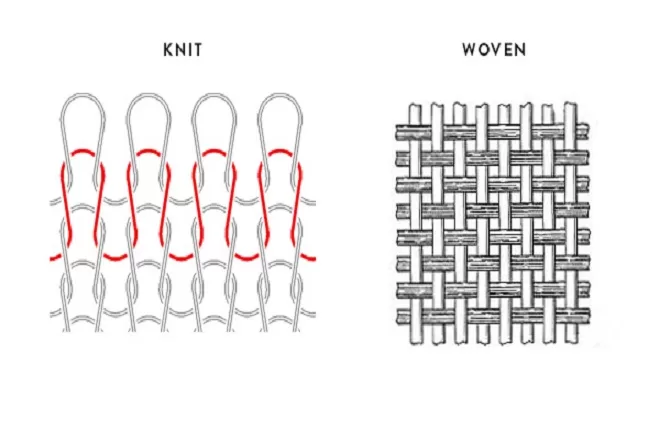

Common backing options for automotive PVC leather include knitted and woven fabrics. Knitted backings are often preferred for better stretch and comfort on seats, while woven backings can offer higher dimensional stability for certain trims.

In addition to the backing, thickness and grain selection is critical:

-

Thickness: must suit the end use. Seat covers and door panels may require different thickness ranges to balance comfort, flexibility and durability.

-

Grain: the surface embossing defines the visual character of the interior. OEM and aftermarket customers often request specific grains that match existing designs or brand identity.

-

Gloss level: from matte to semi-gloss, the right choice helps avoid reflections and gives a premium look.

A professional supplier like Delta Artificial Leather provides:

-

Multiple backing options adapted to chairs, door panels and headliners

-

Different thickness ranges for each application

-

A wide selection of grains and gloss levels to match OEM interiors or create unique aftermarket designs

By optimising backing, thickness and grain together, buyers can achieve both functional performance and the desired visual effect.

Common Mistakes When Buying Cheap Synthetic Leather

Price is always an important factor, but choosing the cheapest synthetic leather can easily become the most expensive decision in the long term. Some common mistakes include:

-

Ignoring performance data

Buying PVC leather without asking for test reports on abrasion, colour fastness or flammability can lead to unexpected failures after installation. -

Focusing only on colour and grain

A beautiful sample book does not guarantee technical performance. If the material cracks, fades or delaminates, the initial saving disappears quickly. -

Not checking backing compatibility

A backing that looks fine at first may not work well with your lamination process, your foam or your sewing lines, leading to wrinkles, poor adhesion or tearing. -

Overlooking production consistency

Some low-cost suppliers cannot maintain the same quality from batch to batch. Variations in thickness, colour or gloss can create visible differences within the same vehicle. -

Underestimating after-sales risk

Complaints, rework, warranty replacements and damage to brand reputation usually cost far more than the price difference between a low-grade and a high-quality PVC leather.

By working with an experienced manufacturer that understands automotive requirements, buyers can avoid these mistakes and protect both their margins and their reputation.

How Delta Artificial Leather Supports OEM and Aftermarket Projects

Choosing the right material is easier when you have a partner who understands both technical and commercial aspects of the automotive interior business. Delta Artificial Leather supports OEM and aftermarket projects in several ways.

Sample Development and Colour Matching

Every project starts with the right look and feel. We offer:

-

Development of custom colours based on physical samples or colour codes

-

Matching of existing OEM interior colours for replacement or accessory programs

-

Different grains and gloss levels to harmonise with dashboards, trims and textiles

Customers can evaluate lab samples before moving to larger trial productions, reducing risk and saving time.

Minimum Order Quantities and Lead Times

Different customers have different needs:

-

OEM suppliers may require higher volumes with regular call-offs.

-

Aftermarket brands and seat cover manufacturers often work with smaller batches and more frequent colour changes.

Delta Artificial Leather offers flexible minimum order quantities and realistic lead times to support both types of customers. This flexibility helps buyers manage stock levels, test new designs and react quickly to market trends.

Requesting Samples and Technical Data Sheets

To make an informed decision, buyers need transparent information. For every relevant article, we provide:

-

Technical Data Sheets (TDS) including thickness, backing type, weight and key performance data

-

Test reports for abrasion, colour fastness, flammability and other requested properties

-

Physical samples and sample books for design and comfort evaluation

Customers can easily request samples and data sheets through our contact channels. Our technical and sales teams help them select the most suitable PVC synthetic leather for each application.